1、 Equipment introduction:

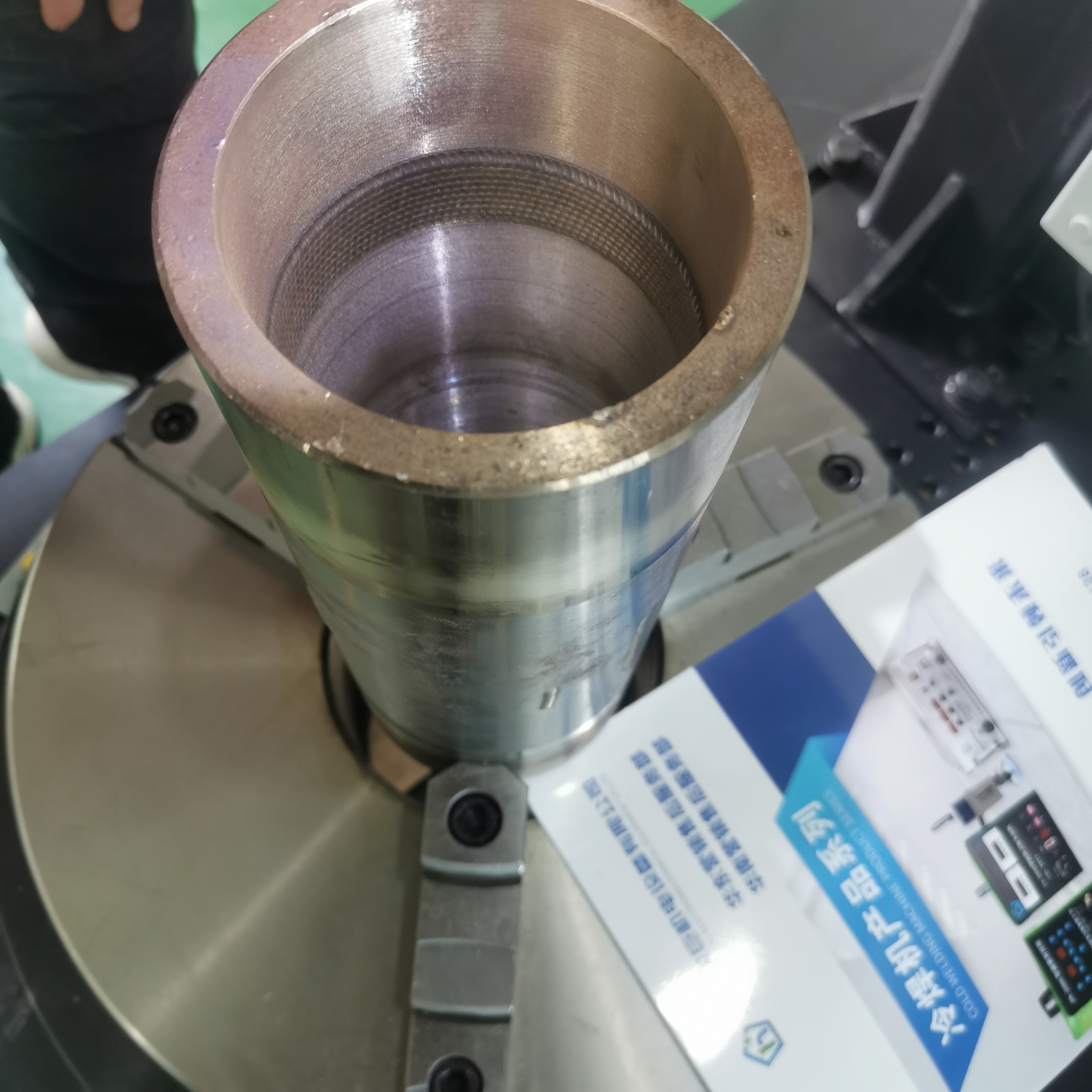

Automatic inner hole welding machine is a surfacing equipment developed by Shanghai Ruiju Electromechanical Equipment Co., Ltd., which is specially used for repairing welding or wear-resistant and corrosion-resistant layer on the inner wall of round hole of workpiece.

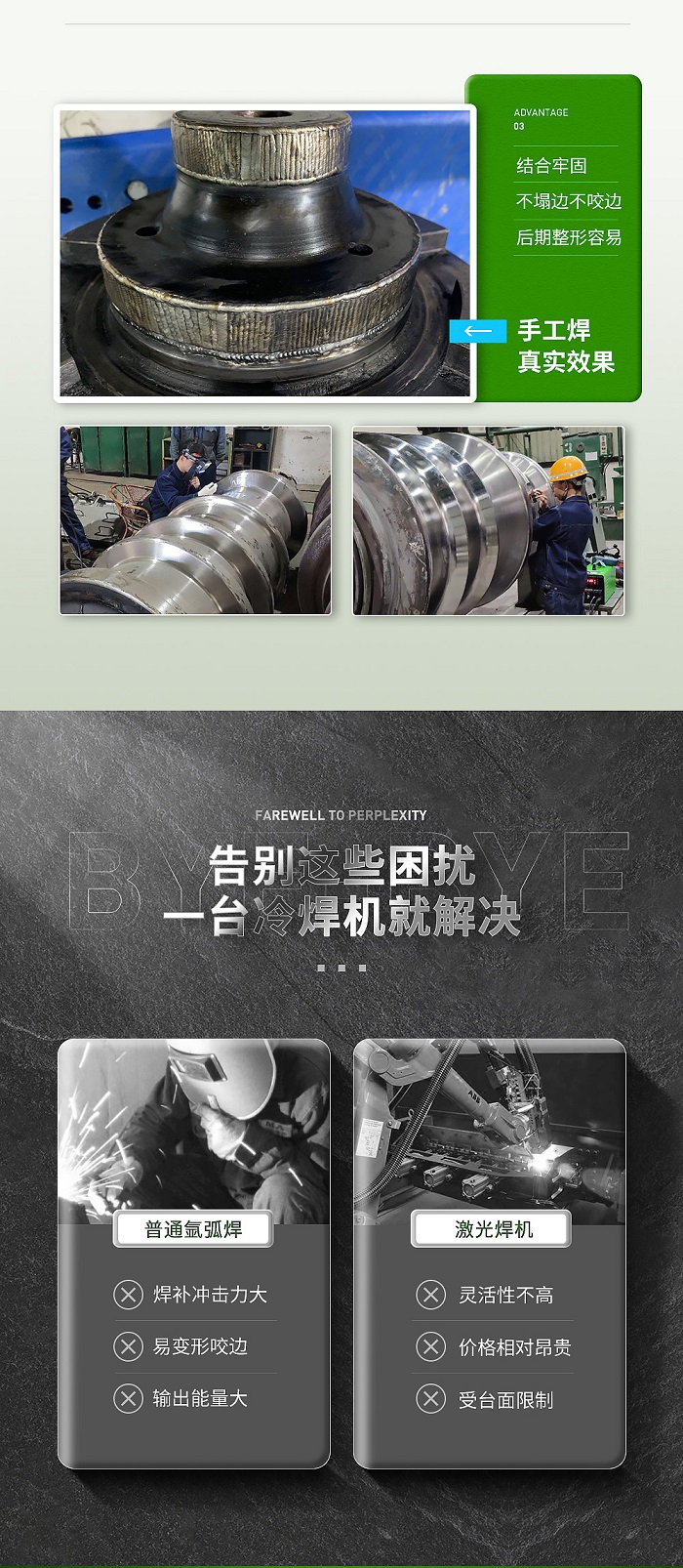

The system uses cold welding equipment as welding power supply, which not only retains the advantages of cold welding, but also improves the welding repair speed.

At the same time, the system is equipped with a weld height tracking system, which does not need to be adjusted even if the welding gun goes deep into the workpiece.

2、 Equipment configuration:

Cold welding power supply: ensure that the workpiece matrix will not change after surfacing; There will be no secondary defects on the surfacing surface after welding;

CNC wire feeder: ensure accurate delivery of welding wire during surfacing, reduce runout and error;

Cooling circulating water tank: provide long-term cooling demand;

Weld height tracking system: automatically adjust the height of welding gun in the whole surfacing process to ensure the quality of surfacing process;

Imported linear guide rail, worm, reducer, etc. make the whole surfacing process stable and reliable.

3、 Applicable products:

It is applicable to the wear repair of the outer circle, inner hole and end face of general shaft parts and pipe parts, as well as the surfacing of wear-resistant layer and corrosion-resistant layer. It can also be used for the surface surfacing and repair of disk parts.

4、 Equipment surfacing effect:

简体中文

简体中文