Electric spark surfacing repair machine

Zy-18 intelligent electric spark surfacing repair machine is a high-power digital cold welding machine developed by Shanghai Ruiju Electromechanical Equipment Co., Ltd. for the metal industry. The machine has powerful storage function and can store a variety of welding repair modes. The input power reaches 3000W, and the welding repair efficiency is more than twice higher than that of similar products. It is an intelligent cold welding machine with high cost performance and high efficiency that can really reduce production costs for enterprises.

Advantages over similar welding machines:

a) The input power of the machine is 1800 watts and the standby power is 15 watts.

b) The pulse width range is 20-100us and the frequency range is 40-300hz.

c) Full digital control, can store a variety of welding repair modes.

d) The applicable range of welding wire is 1.2-3.6mm.

e) The welding gun is not hot when it works continuously for 8 hours. (the welding gun is cooled by air cooling)

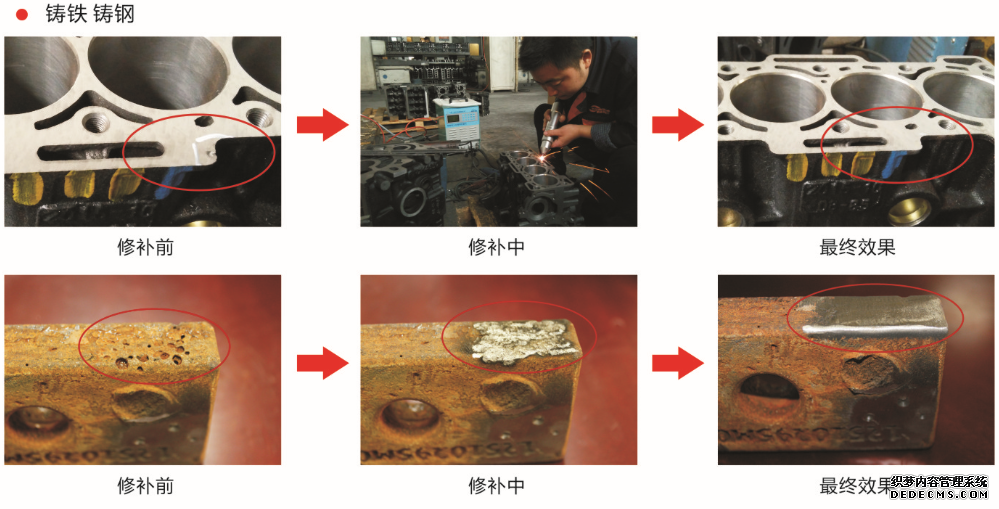

Cast products: cast metal products can be applied to this welder.

Automotive parts products: repair of casting defects such as oil nozzle, crankshaft, piston, cylinder block, intake and exhaust pipe and brake disc in the automotive industry, such as sand hole, air hole, etc.

Machinery industry and machine tool industry: correct out of tolerance or worn workpieces, such as repairing machine tool guide rails and bed, shaft and tooth parts of large machinery, cold and hot rolling rollers for steel rolling, hydraulic rods of construction machinery, printing press rollers and other spare parts.

Aviation and shipbuilding industry: compressor shell, air compressor shell, stainless steel precision parts, precision shafts, etc.

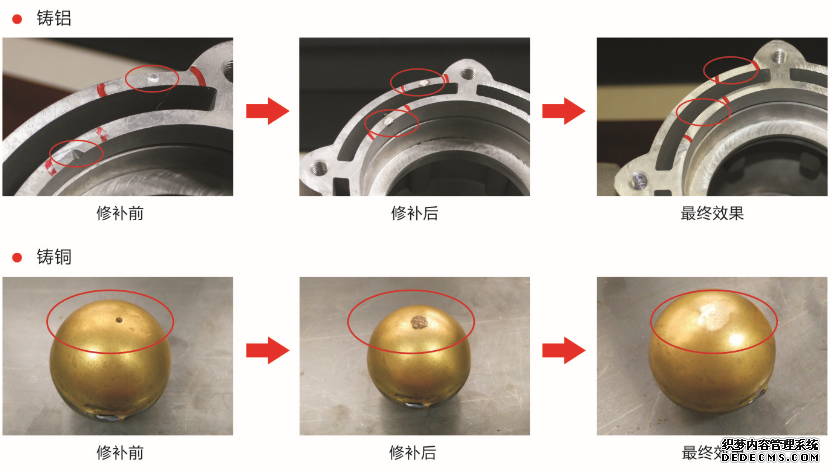

Nonferrous metal parts in various industries: such as aluminum alloy parts of SF6 transformer in power industry, aluminum alloy cylinder block, cylinder head and hub in automobile industry, aluminum alloy impeller of fan, aluminum alloy radiator, etc. Copper alloy plumbing valves, pipe fittings, etc.

Injection mold: welding repair of wear, bruise and scratch of the mold to eliminate flash and burr of the product.

Die casting die: the corrosion mark, falling off and damage of zinc aluminum die casting die, as well as the surface strengthening of mold cavity and sprue gate, so as to prolong the service life of the die.

In addition, the products of petrochemical, coal, construction machinery and many other industries are repaired.

简体中文

简体中文